What Are the Parts of a Forklift and What is Their Purpose?

Published by OrangeParts.com on 2nd Oct 2024

Figuring out which part number you need when ordering forklift parts can be challenging. Every day, we receive countless phone calls, emails, and chat messages from people seeking assistance in identifying the correct part numbers for their forklifts. Knowing the names and functions of the various parts of your forklift can significantly ease the process of ordering the correct parts. At OrangeParts.com, we understand how important it is to quickly identify forklift components to minimize downtime. In this post, we will break down the key parts of a forklift, explaining what they are and their purpose. Whether you have an LPG or electric forklift, understanding these parts will help you become proficient in identifying the components you need for maintenance or repairs.

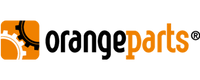

In the image, you’ll see a standard forklift with its key components highlighted. This particular model is a propane/LPG-powered forklift, identifiable by the LPG tank mounted at the rear.In Europe, roughly half of the forklifts produced are electric. These electric models look almost identical to the one shown, except they don’t have the LPG tank at the back. Three-wheeled forklifts also have a similar overall appearance.

The Mast

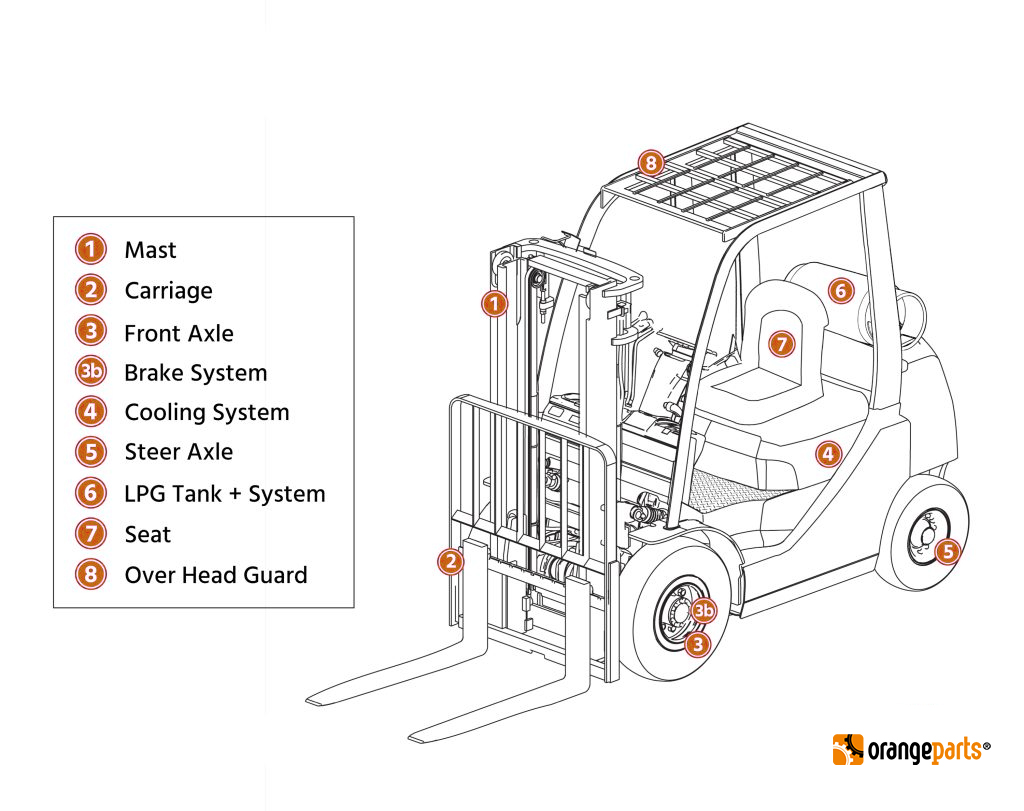

The mast is one of the most important parts of any forklift. It’s the vertical structure at the front of the forklift that supports the lifting and lowering of loads. Forklift masts come in various configurations, with the 3-stage mast being the most common in the U.S.

Forklift masts use hydraulic cylinders to operate. When ordering parts such as seal kits (also known as packing kits) for mast cylinders, it’s crucial to know whether you need them for the main lift cylinder or the free lift cylinder. The main lift cylinder handles the bulk of the lifting, while the free lift cylinder allows for finer adjustments without raising the entire mast. Keeping seal kits on hand ensures your forklift mast continues operating smoothly, minimizing downtime.

2. The Carriage

The carriage is where the forks are mounted, and it moves up and down the mast. It includes mast rollers (also known as carriage rollers or mast bearings) that roll inside the mast channels. These rollers are essential for the smooth movement of the carriage as it lifts and lowers loads.

Most forklifts are equipped with a sideshifter, which allows the forks to move laterally, making it easier to position the load. In addition, a load backrest (LBR) helps keep the load stable, preventing items from falling back toward the operator. Ensure that your forklift’s carriage and its components, such as the sideshifter and backrest, are in good condition to maintain safe and efficient operations.

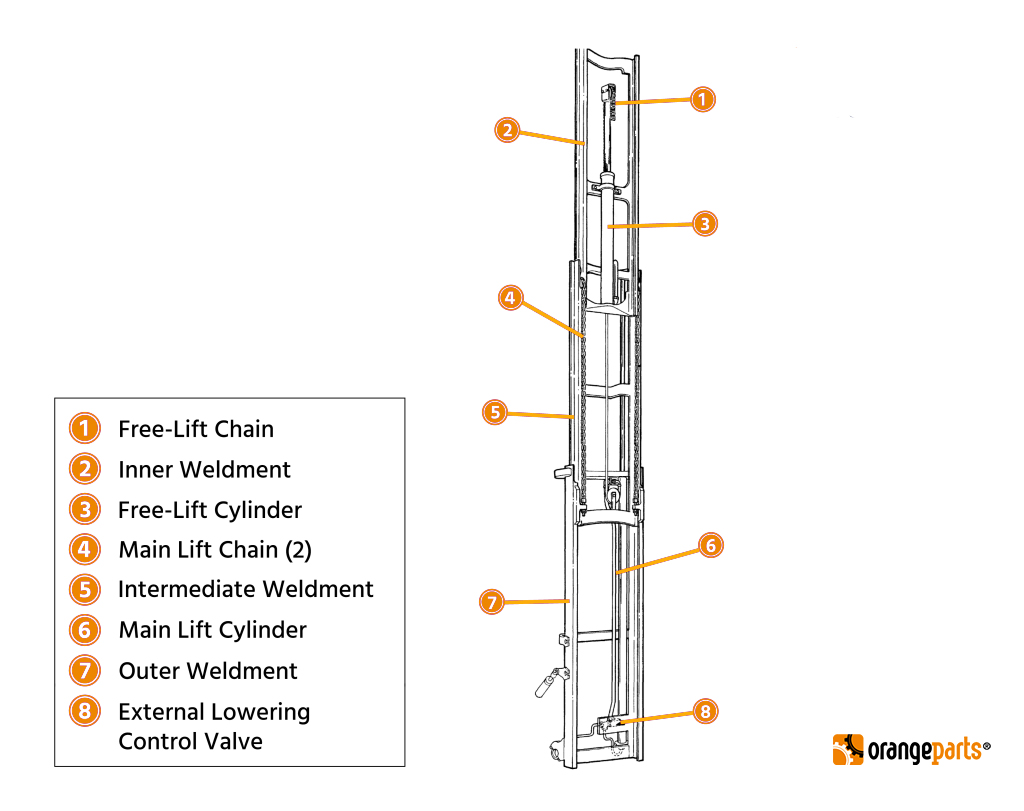

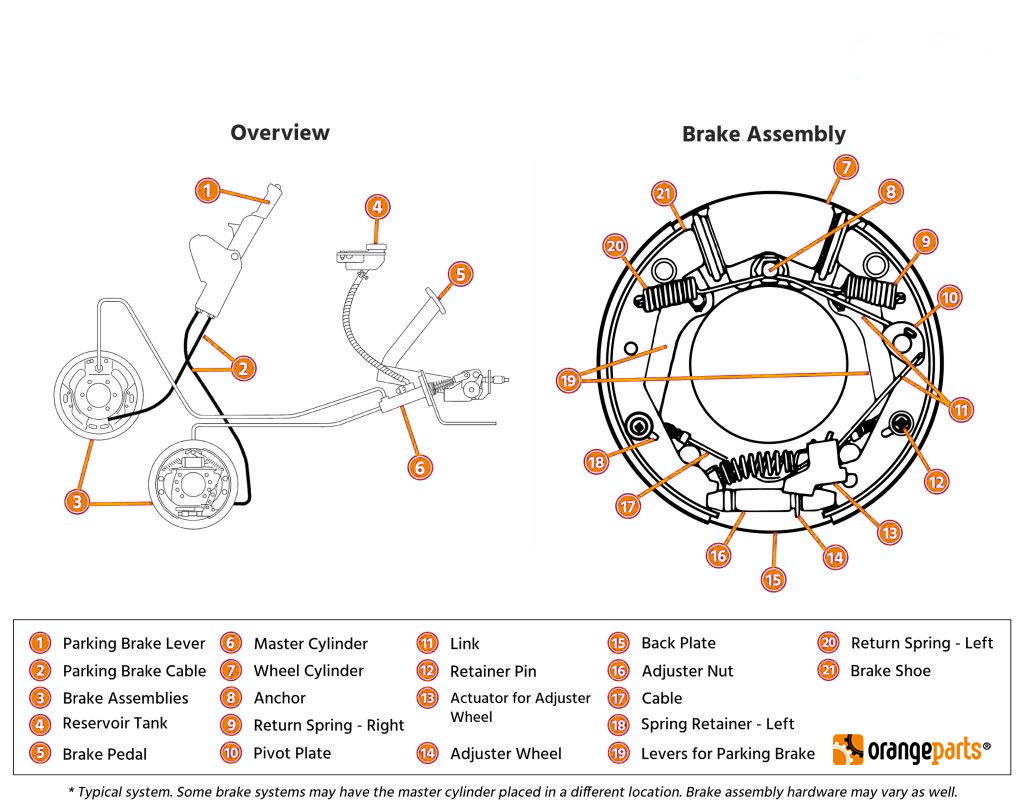

3. Front Axle and Brake System

The front axle (also known as the drive axle) is responsible for driving the forklift forward. It also contains one of the most frequently serviced components on any forklift: the brake system. Forklifts typically use drum brakes, and over time, the brake shoes, drums, and wheel cylinders will wear out and require replacement.

When servicing the brake system, it’s important to check the master cylinder and the parking brake, which often use separate cables. Keeping a set of brake shoes, springs, and hardware on hand is a wise choice for quickly resolving any brake-related issues that may arise.

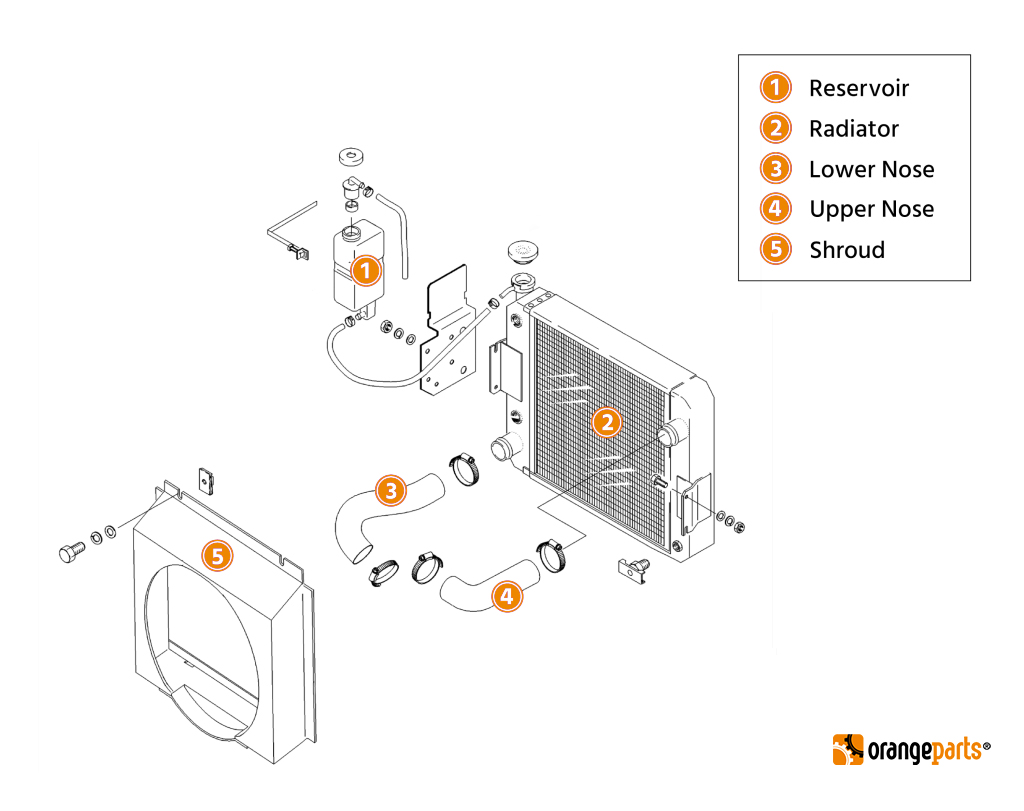

4. Cooling System

Forklifts with internal combustion engines, whether powered by LPG or diesel, have a cooling system that includes a radiator. Radiators are typically made of copper, steel, or aluminum, and they play a vital role in keeping the engine from overheating.

Radiator maintenance is essential, especially when forklifts operate in high-temperature environments. Forklift radiators are often located behind or within the counterweight, which makes them somewhat difficult to access for repairs. Keeping spare radiators or radiator components (such as hoses and fans) available ensures that any cooling system issues can be quickly addressed, preventing potential engine damage.

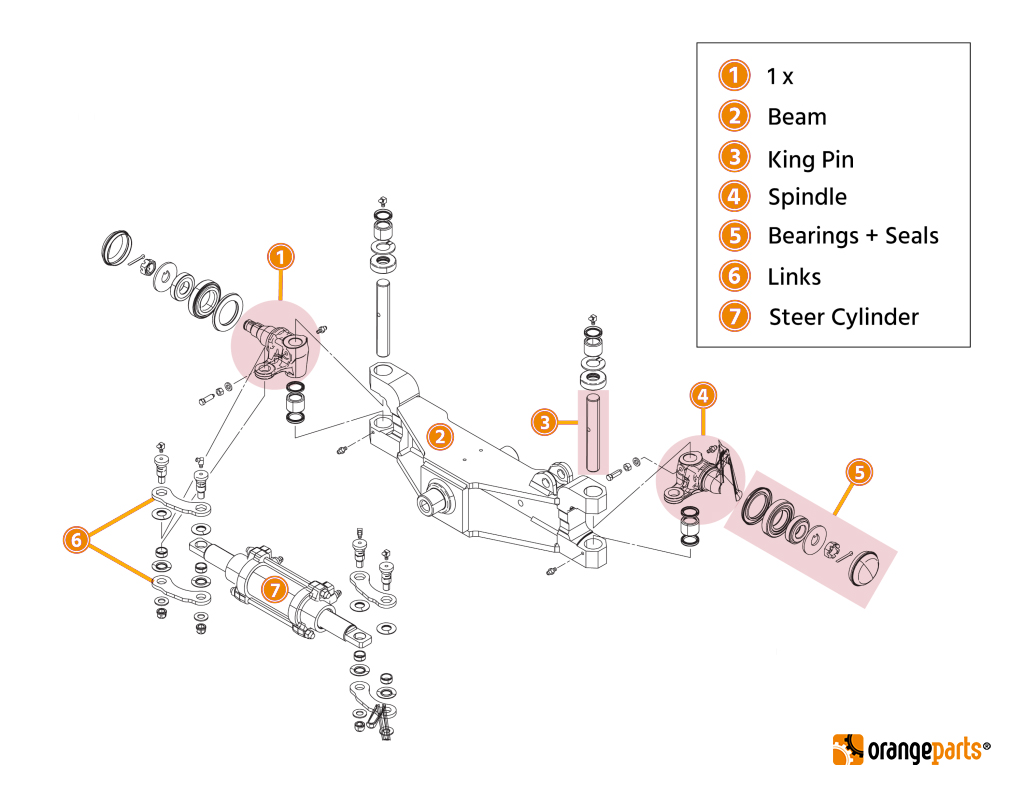

5. Steer Axle

The steer axle is located at the rear of the forklift, opposite the drive axle. Unlike other forklift components, steer axles are custom-made by the manufacturer and vary between models. The steer axle consists of a steering cylinder, spindle, and tie rods, which connect the axle to the wheels and allow for smooth steering.

If your forklift’s steering becomes sloppy, it’s often due to wear in the steering components, and rebuilding the steer axle may be necessary. You can avoid downtime by keeping steer axle pins, tie rods, or even a complete replacement steer axle in your inventory.

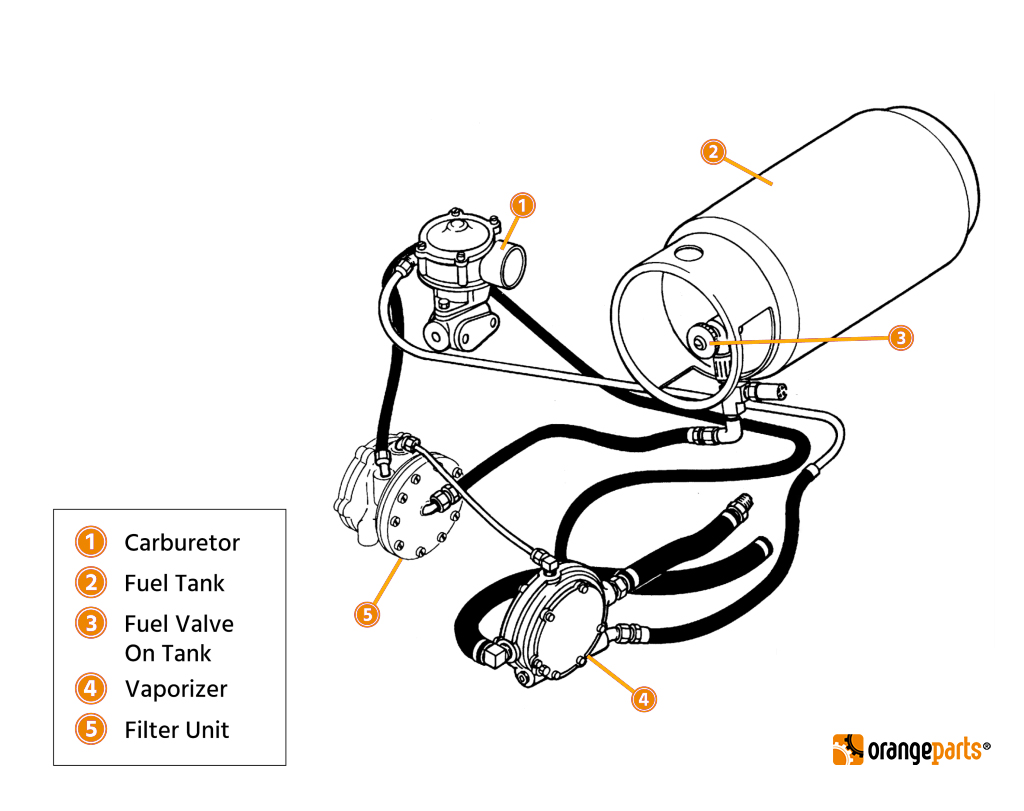

6. LPG Tank and Fuel System

For LPG-powered forklifts, the LPG tank and its associated fuel system are critical components. Forklifts with propane engines use a system of regulators, vaporizers, and filters to convert liquid propane into gas for combustion.The most common propane fuel system is manufactured by Impco, and it consists of parts such as the Impco Model J vaporizer and the VFF-30 filter. Having spare filters, carburetors, and vaporizers is essential for maintaining the performance of your LPG-powered forklift, particularly if it was manufactured before 2010.

7. Tires

Forklift tires are one of the most frequently replaced parts. Pneumatic tires are used for outdoor environments with rough terrain, while solid tires are more common for indoor applications on smooth surfaces. Over time, both types of tires wear down and require replacement. Having spare tires available ensures that you can replace worn-out tires immediately, reducing downtime.

8. Hydraulic Hoses and Lift Chains

The forklift’s hydraulic system powers the lifting functions of the mast and any attachments such as clamps or rotators. Hydraulic hoses can wear out or develop leaks, and lift chains that raise the mast can become worn or stretched over time. Replacing worn-out lift chains and hydraulic hoses is critical for maintaining the lifting power and safety of your forklift.

9. Filters: Air, Oil, and Fuel

Just like in any other vehicle, the air filters, oil filters, and fuel filters on a forklift play a vital role in keeping the engine clean and running efficiently. Keeping spare filters in stock ensures that your forklift’s engine continues to operate smoothly without any interruptions caused by dirt or contaminants.

Conclusion

Knowing the key components of your forklift and their purpose will make ordering parts at Orangeparts.com easier and more efficient. From masts and carriages to axles and hydraulic systems, each part plays a crucial role in keeping your forklift operational. Having essential spare parts on hand, such as brake components, tires, filters, and hydraulic hoses, ensures that you can perform quick repairs and maintenance, minimizing costly downtime. Keep your forklift fleet in top condition by staying proactive and stocking the right parts for the job.